How is Fine Bone China Made?

How is the fine bone china made?

The evolution of bone china design begins with a simple sketch. Once the design is complete on paper, the initial model is shaped by hand in Plaster of Paris. This is an incredibly skilled process, and takes over five years to learn the technique.

In a multi-stage process, quality raw materials are selected

and crushed before being passed through a series of screens to remove any over

or under sized particles. Next, water is added to the materials producing liquid

clay, known as slip, and is now ready to be formed into the fine bone china

pieces.

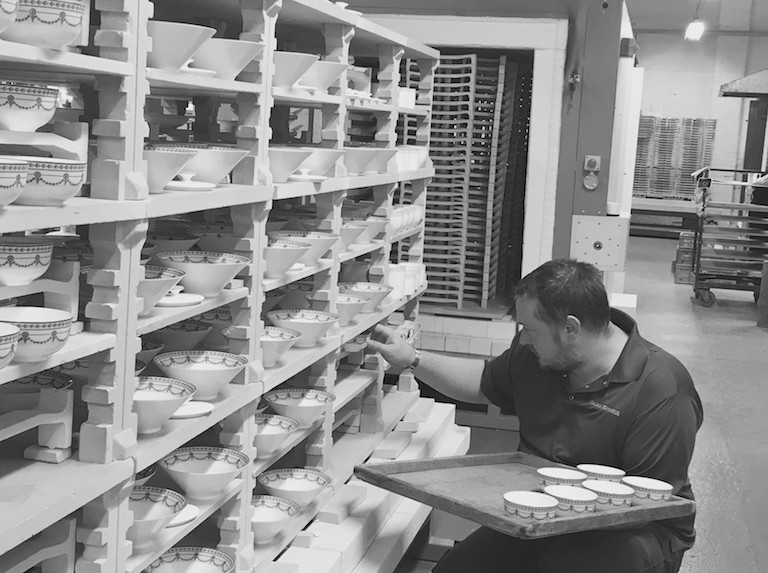

The flatware pieces such as plates and bowls are produced on a jigging machine. The hollowware pieces, such as jugs and cups, are formed by pouring the slip into two-part plaster moulds. Once dried, the pieces are removed and gently trimmed. The two pieces of clay are then painted with casting slip and put firmly together, eliminating any air.

How is the Pattern on the Fine Bone China Designed?

Our in-house design team derives its inspiration from many

sources. The decoration on our fine bone china ranges from classical Palladian

architecture, to 1950’s cake baking, to minimalist contemporary white bone

china. There is an original

William Edwards Home collection to complement every

style of interior.

We also offer ranges of fine giftware inspired by memorable events such as the imminent Royal wedding and the 100th Anniversary of the Royal Air Force, making these collections the perfect present.

Each pattern starts with a simple sketch that gradually

becomes more detailed and is eventually refined on the computers in our digital

design studio. The selected designs are adapted to the individual pieces of

chinaware, and silk screens are then produced for each individual colour in the

pattern and printed onto lithograph paper. The lithographs are carefully slid off

the waterslide membrane and applied by hand to the blank fine bone china before

being fired in the kiln at 800°C for 16 hours.

The gold edging is then burnished using brushes on a polishing machine, then, the back stamps are applied, stating the William Edwards name, the pattern, and where it was made. Finally, the pieces are fired in the kiln at 780°C for 16 hours. After a final scrupulous inspection, the items are packed into individual gift boxes and despatched to the customer.

Overall, the fundamental difference separating us from competitors is our attention to detail and our talented William Edwards in-house team who are at the cutting edge of design. This results in unique, quality products.

To find out more about the William Edwards Home collection, click here.